The device needed here is called a register plate. It's very simple, just a heat-proof sheet of something across the chimney, around the flue pipe, closing up the gaping hole. I had my eye on a suitable piece of metal: We replaced our washing machine when the old one rusted through in a critical place, and I fancied that a side panel from the old machine would be ideal for a register plate. Step one was to dismantle the old machine, which was a lot of fun.

At this point I discovered that the case didn't come apart into panels easily and would need cutting, which was a bit of a pain. I tried using a hand saw, which was effective if very slow. It might have been quicker if the saw hadn't been missing so many teeth. We then got hold of some metal-cutting blades for a borrowed jigsaw. That was much quicker and extremely loud. Earplugs were deployed. Eventually I had not only cut a suitably sized sheet, but also cut a hole in it for the flue to go through.

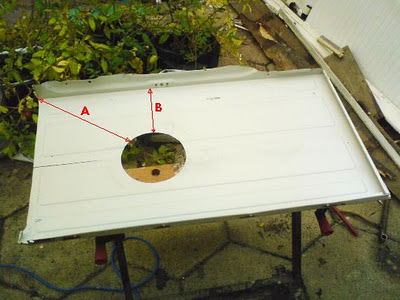

Register plate, neatly cut out. Ian also cut a smaller rectangular piece to sit on top of and extend the short side.

At this point I was feeling very pleased with myself. Once cut, I then tried to fit the plate into the chimney. At this point I discovered why neither of the tradesmen had fancied this job. Let's take another look at that plate:

Consider that 'B' is the distance between the back of the flue pipe and the back of the chimney space (it must be, because I cut this plate to fit the space). In order to the the plate in place, the back part of the plate to the left of 'B' must pass through that space. That means that the back left corner must swing round through a space the length of 'B'. Notice the length marked 'A'. There aint no way 'A' is going to get through 'B's space. That didn't stop me trying though.

There was a bit of space for manoeuver in the vertical direction, but not nearly as much as I tried to convince myself there was. The sheet was flimsy enough to bend up out of the way, but limited vertical space meant that wasn't as useful as it might be. After a bit I gave up and cut off a piece at the back, making dimension 'A' roughly the same length as 'B'. There was still a lot of struggling to get it in place (note similar issues with the right hand back corner) and there may have been quite a lot of swearing.

Eventually I forced the thing into position, uncurled the curled-up bit, added the extra rectangle to fill the space on the left, ignored the scratches to the brass soot door on the flue, and stuffed some spare rockwool above it to assist with the heat loss reduction efforts. Apparently I didn't take a photo of this momentous occasion, but you can see the plate lurking behind the holly and sparkly things in this picture:

One slight downside to this design is that the paint on washing machines is not designed to withstand very high temperatures, and smells a bit when the fire gets really hot. On the other hand, that does let us know that the fire's getting really hot! As to whether it works, disappointingly, I can't say we noticed much difference in the sitting room temperature after this was installed, but I'm sure it was necessary. I need to believe that!

Another humourously shared adventure. I really the look of your fireplace - it's beautiful - and am glad you conquered the stubborn 'register plate'.

ReplyDeleteHowever, I'm a bit worried about the paint and fumes. Maybe I'm paranoid about such things, but then, I've seen someone heat a can of paint in garbage fire... the smell was quite strong and definitely not something to inhale... T_T

In any case I hope your heating project is almost at an end, yes?

Aw, thanks :-)

ReplyDeleteMy attitude to the fumes is that there's a limited amount of nasty stuff in one coat of paint, and once that's been driven off we'll be alright after that. In the meantime, we go into another room! It could be worse - we could live in London, breathing traffic fumes all day every day ;-)

The current stage of the heating project is insulation, which I'm struggling to motivate myself to finish. I'm trying not to think too much about the home made solar panels, which are the next stage. If I time it right, my dad may be visiting when I get to those, so he can help me with the tricky bits.